Lucey Silent Slicer

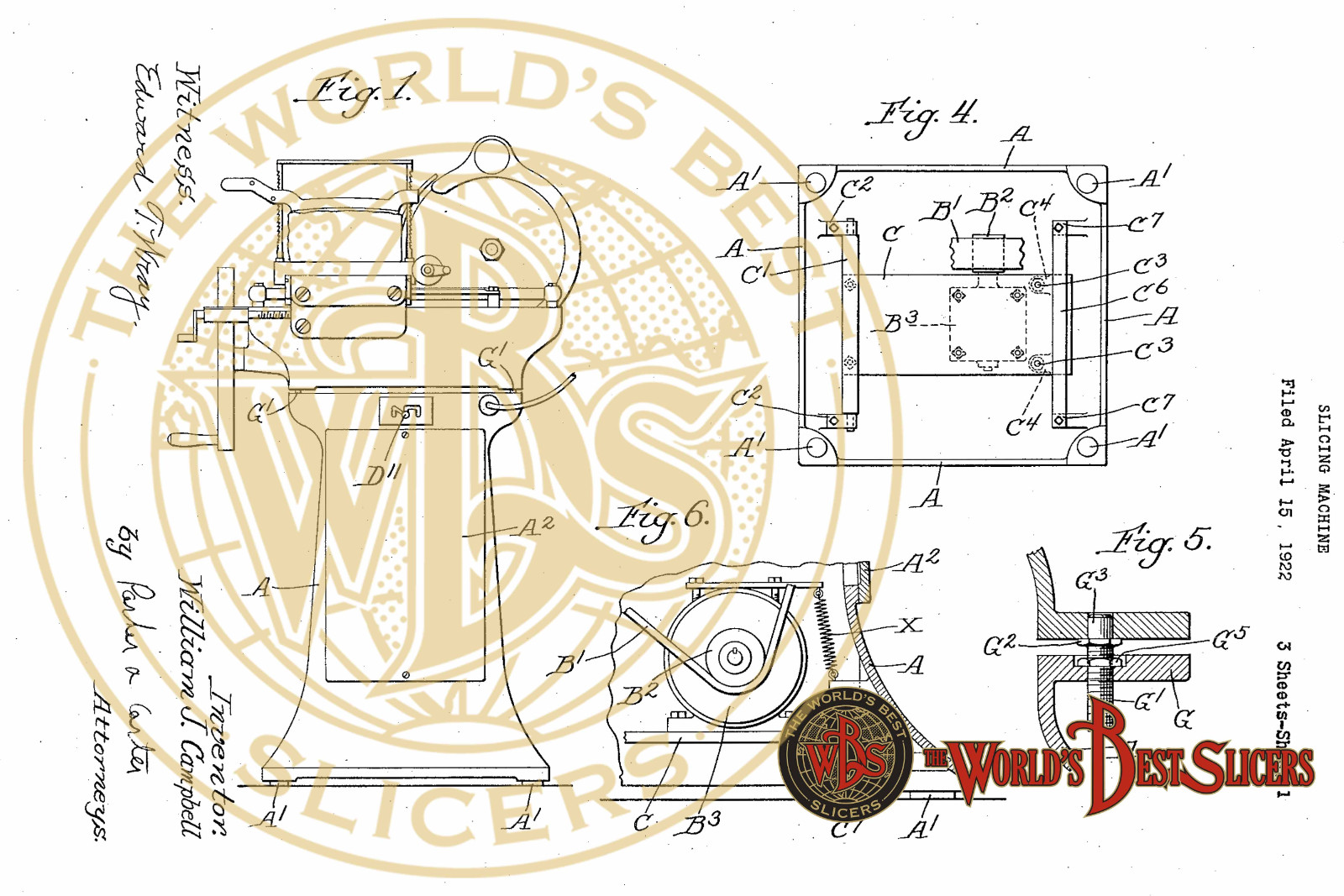

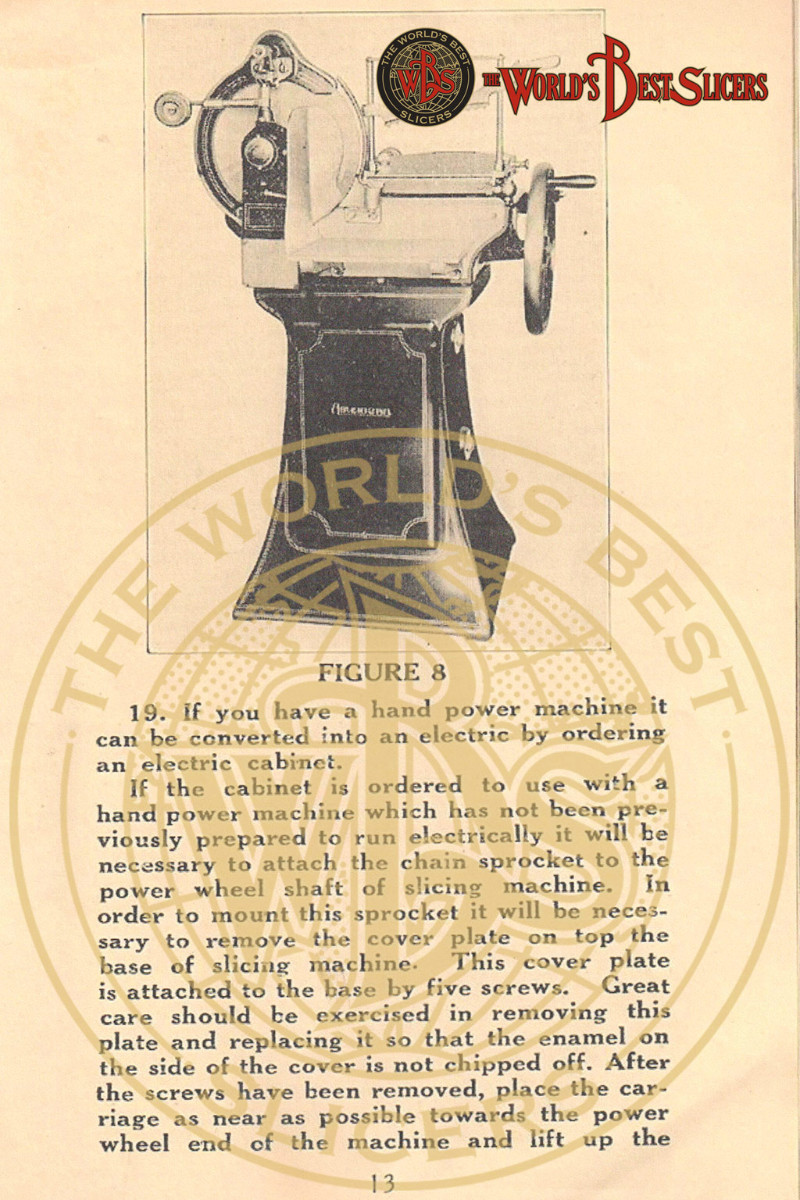

The flywheel slicer Lucey Silent Slicer was produced in the USA in the period from 1925 to 1933 by former workers who worked in the Bekel factories that had decided to produce a flywheel slicer that could be in the choice of the materials used in the construction and realization of the machine itself, both in the design of the mechanics and in the realization of the decorations themselves.

Lucey Silent Slicer

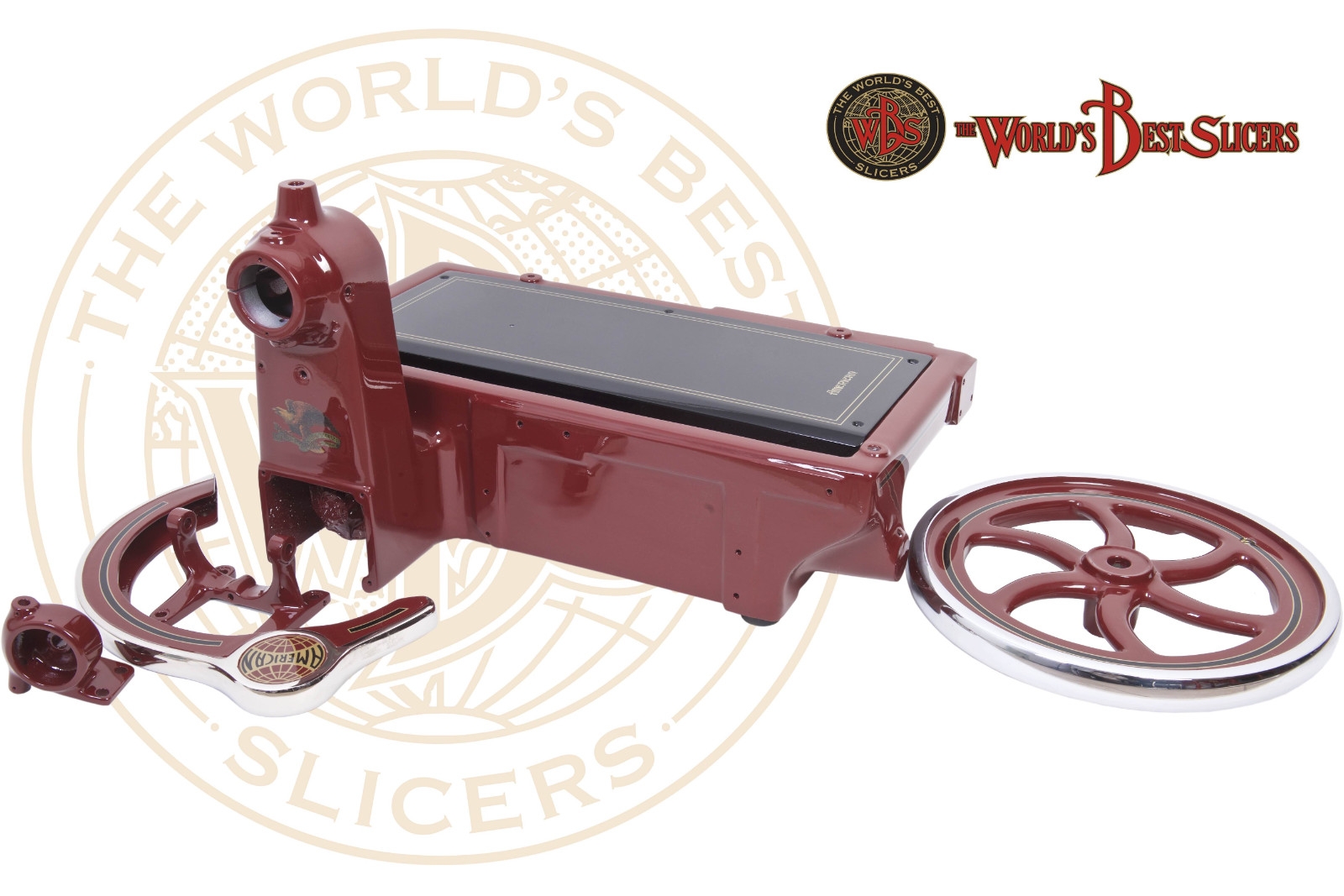

The flywheel slicer Lucey Silent Slicer was produced in the USA in the period from 1925 to 1933 by former workers who worked in the Bekel factories that had decided to produce a flywheel slicer that could be in the choice of the materials used in the construction and realization of the machine itself, both in the design of the mechanics and in the realization of the decorations themselves. This machine, in addition to having a striking appearance, is equipped with a very silent mechanism of sliding and movement of the mechanical parts. As for the quality of cutting has nothing to envy to the close relatives produced by the much more established manufacturer "Berkel" because placing the regulator of the thickness of the slice in the cutting position number 1 we have a product sliced in the thickness of 0.2 mm. So in the same perfection and dimension of the most prestigious Bekel slicers. This machine mounts a blade with 350 mm. of diameter and is provided with the sharpening device fixed on the shoulder, provided with a single large stone that according to the position where it is moved ensures a good sharpening and a consequent deburring of the blade in order to always have a quality cut. This flywheel slicer Lucey Silent Slicer weighs a total of 105 kg.The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee