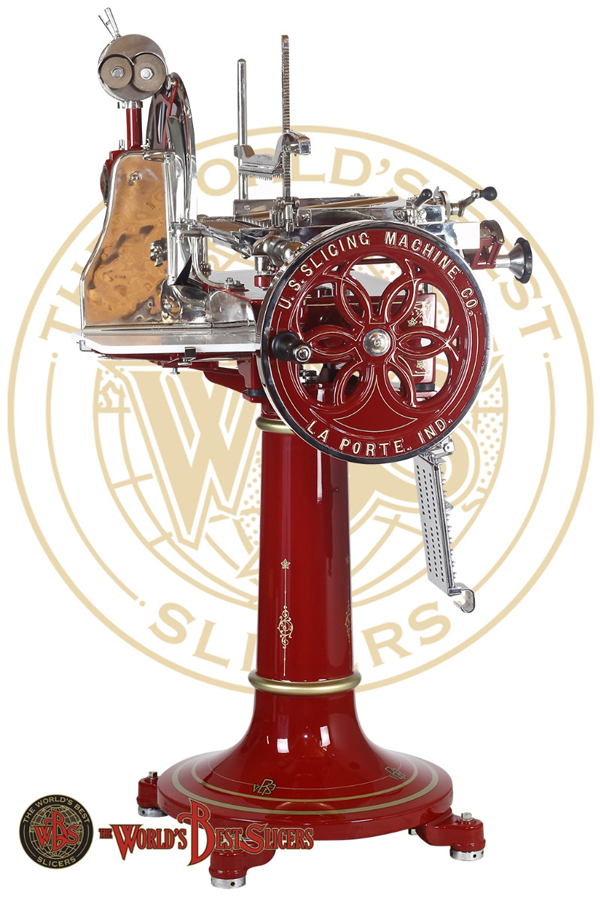

Berkel Model E USA

The US Berkel model E flywheel slicer was built in the period from 1930 to 1935 in the La Porte – Indiana and Toronto – Canada factories. The slicer Berkel model E US is a variant of the American Berkel model C and retains many of its construction features.

The US Berkel model E flywheel slicer was built in the period from 1930 to 1935 in the La Porte - Indiana and Toronto - Canada factories. The slicer Berkel model E US is a variant of the American Berkel model C and retains many of its construction features. The US Berkel flywheel slicer mod. E US features a blade of 370 mm. in diameter and has a cutting capacity of 265 mm. The Berkel US model E has an apparatus for sharpening the blade in the upper part of the shoulder. This slicer has a 24-position slice thickness adjustment, located directly on the right side of the trolley. The US Berkel mod. E is driven by a closed flywheel with a diameter of 340 mm. with the writings applied in decal US Slicing Machine Co La Porte Ind. and was produced in red and green, the metal parts are originally chromed. The US Berkel mod. E has a total size of 880 mm. length 650 mm. width and 660 mm. height and requires a support of 280 mm. width 500 mm. length. The flywheel slicer Berkel Model E USA weighs 100 kg overall. Like most slicers produced by Berkel separately, its original stand was supplied, equipped with height adjustment for each individual support foot, to be positioned perfectly level on any type of flooring, even the most uneven ones in a short time. The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of worn or broken pieces, carrying over material through welding and subsequent milling or turning of the pieces to be able to restore them to their original dimensions and functionality. For missing parts, original spare parts acquired from production plants or from incomplete slicers are used. The painted parts, which were first stripped of paint by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly carried out through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee.