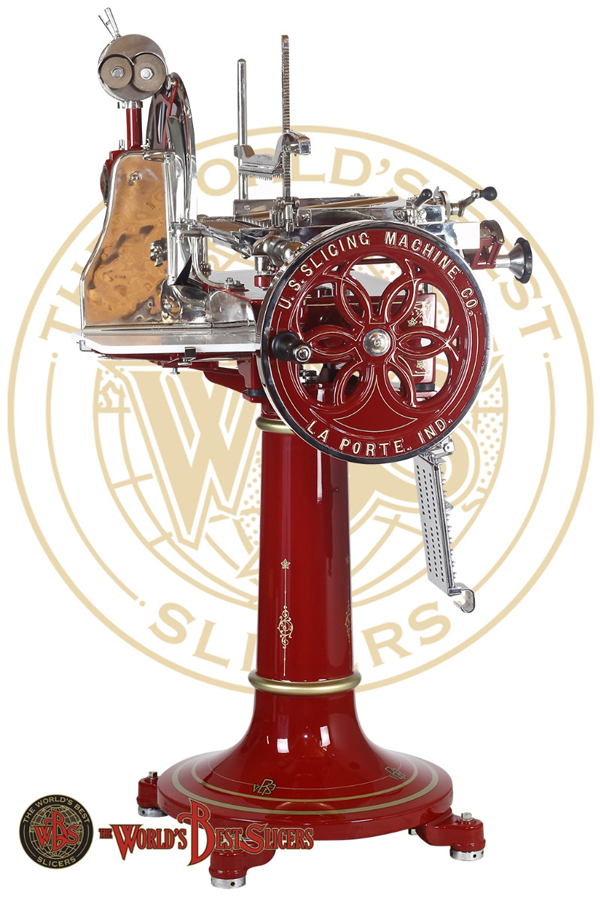

Berkel – USA Canada Model 100

The flywheel slicer U.S. Berkel model 100 is built in the period from 1918 to 1925 in the factory of “La porte” in the state of Indiana. The model 100 has a blade of 350 mm. and 370 mm.

Berkel - USA Canada Model 100

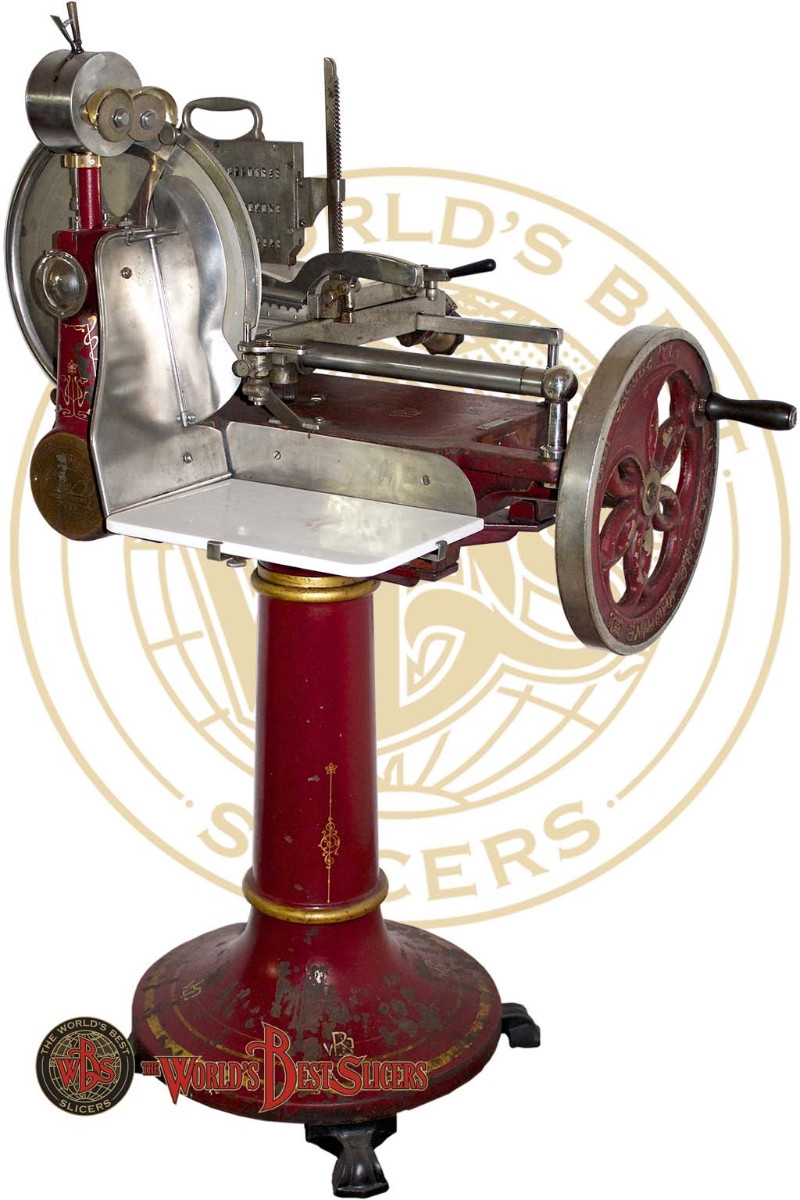

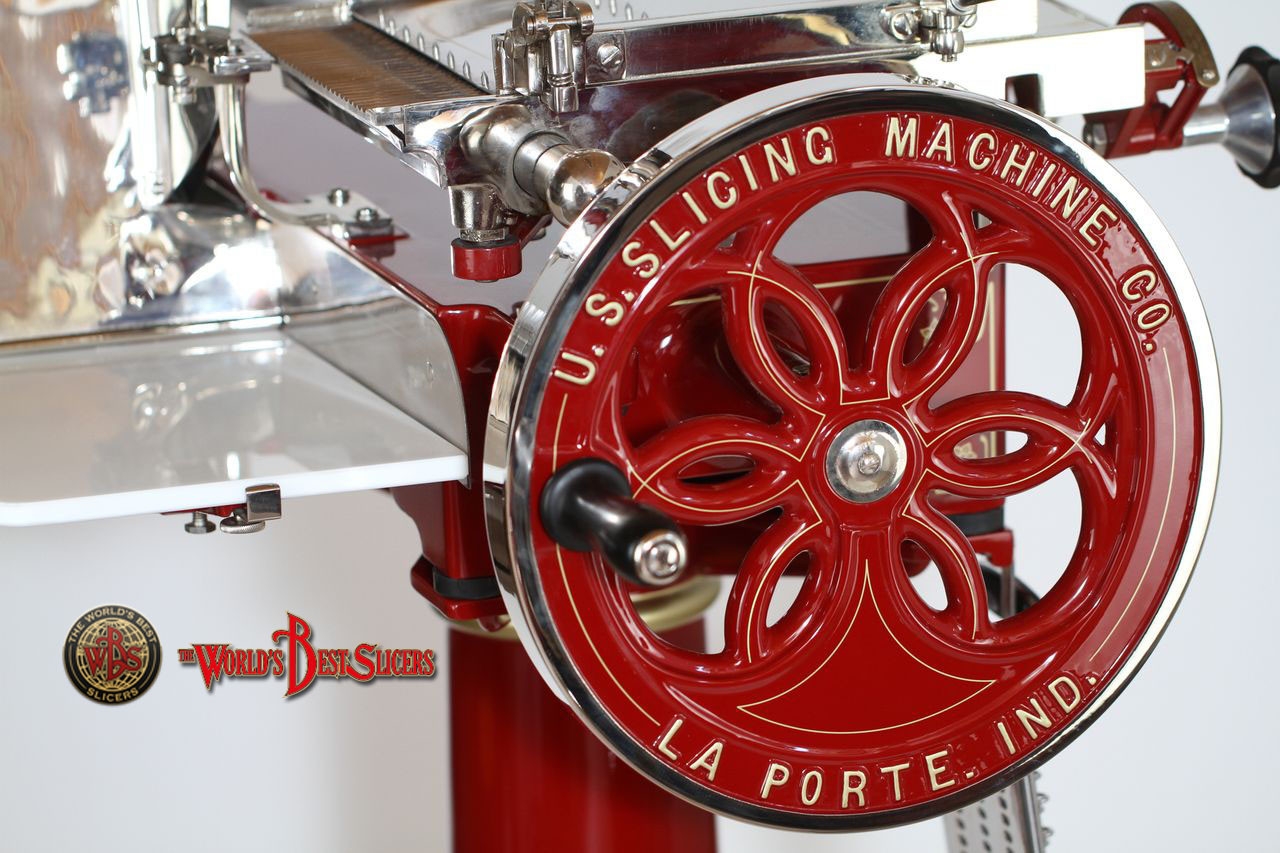

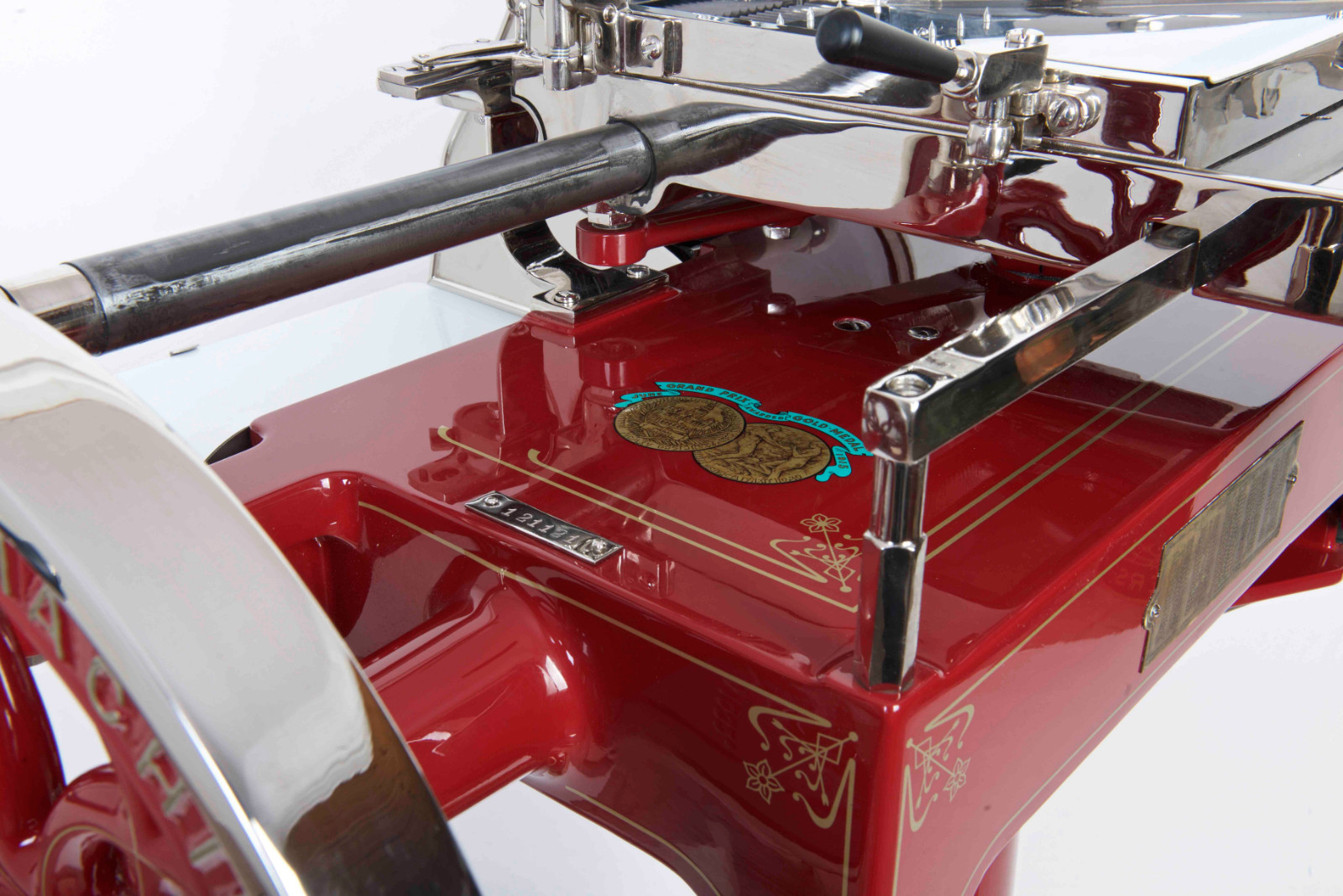

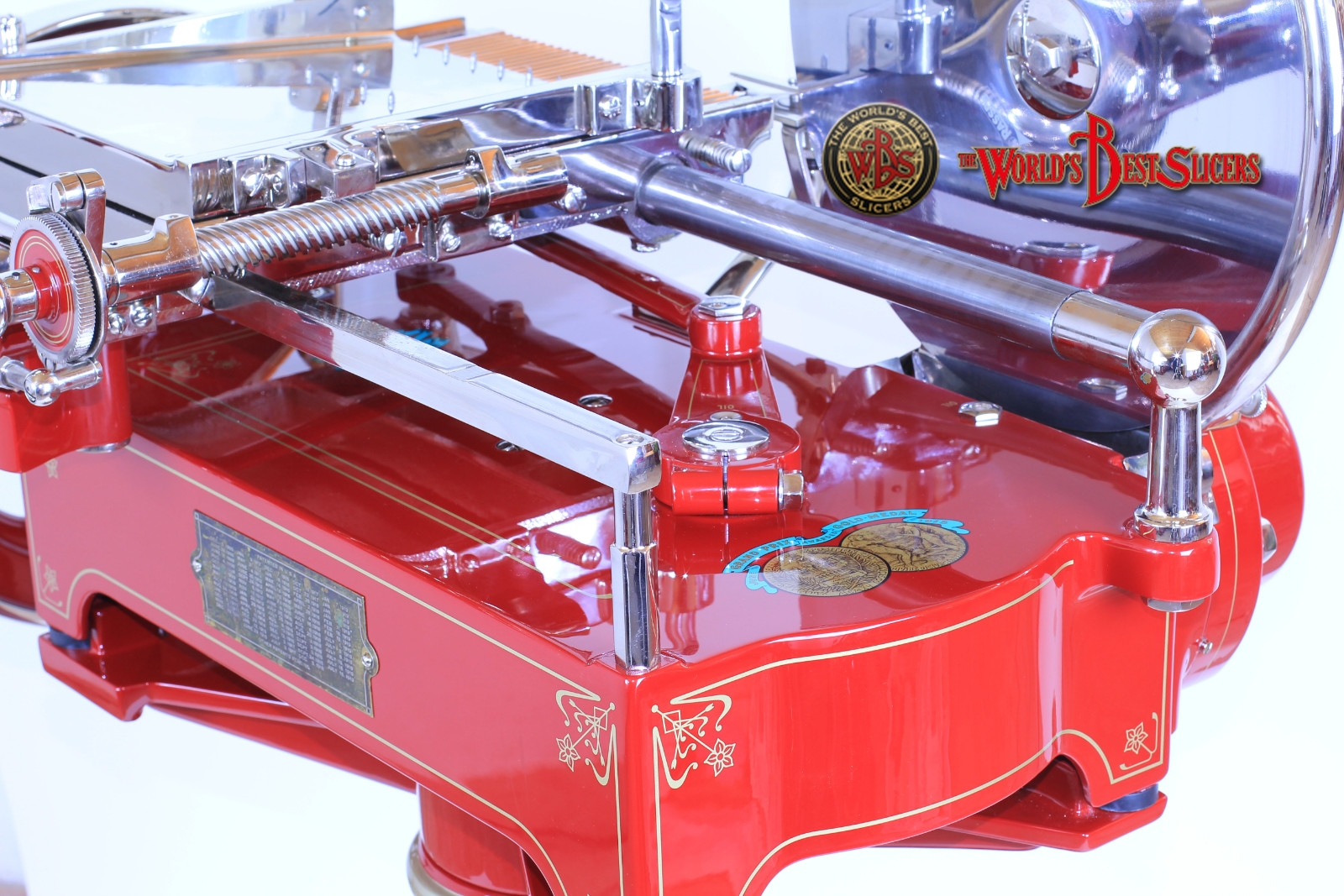

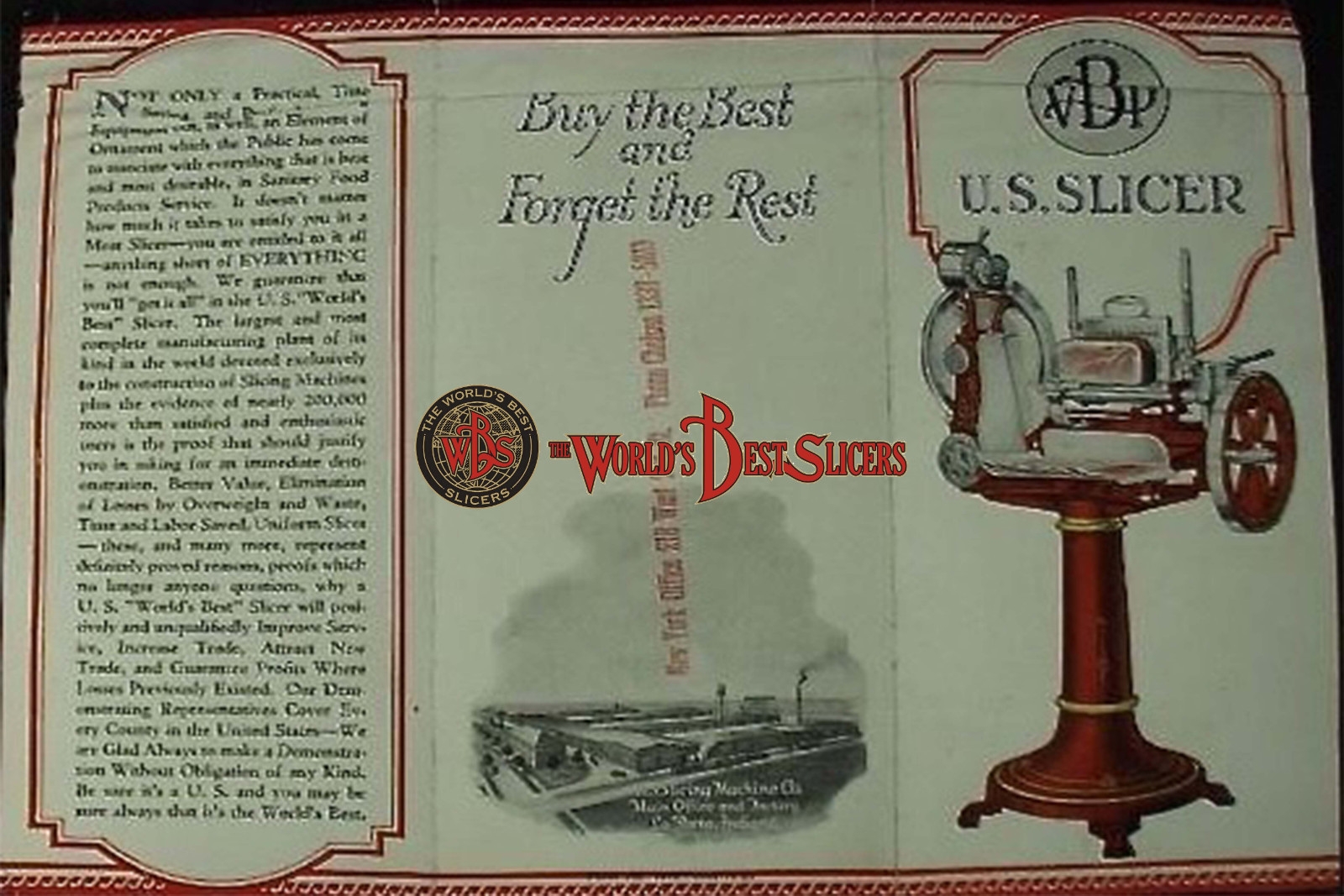

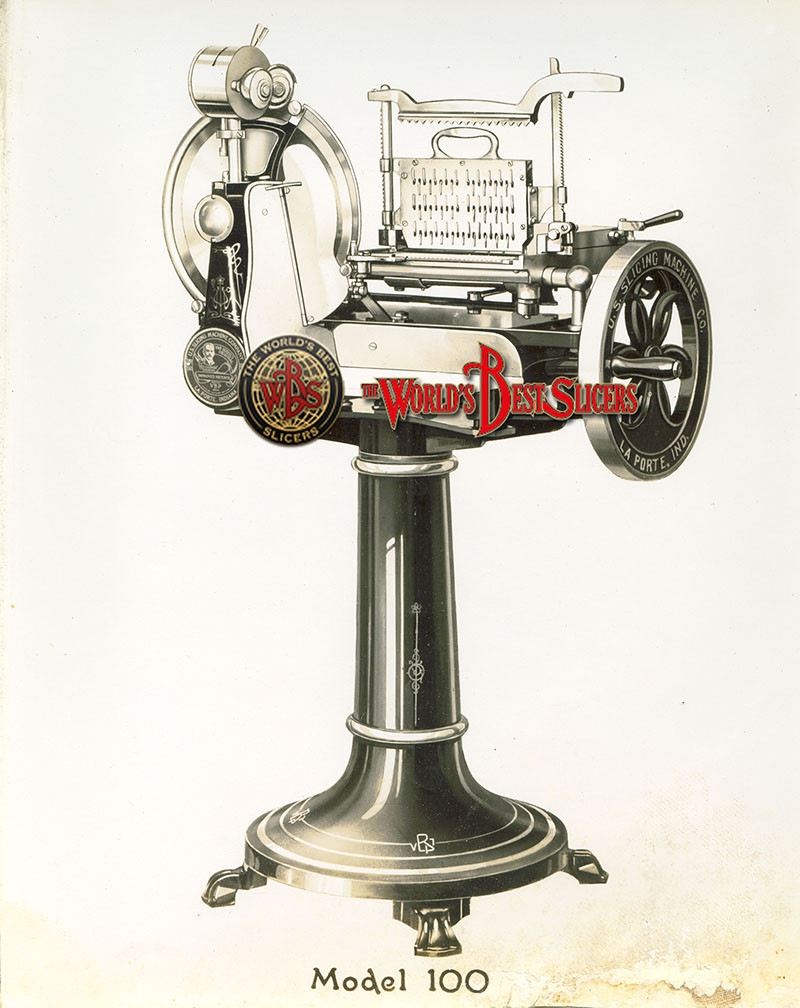

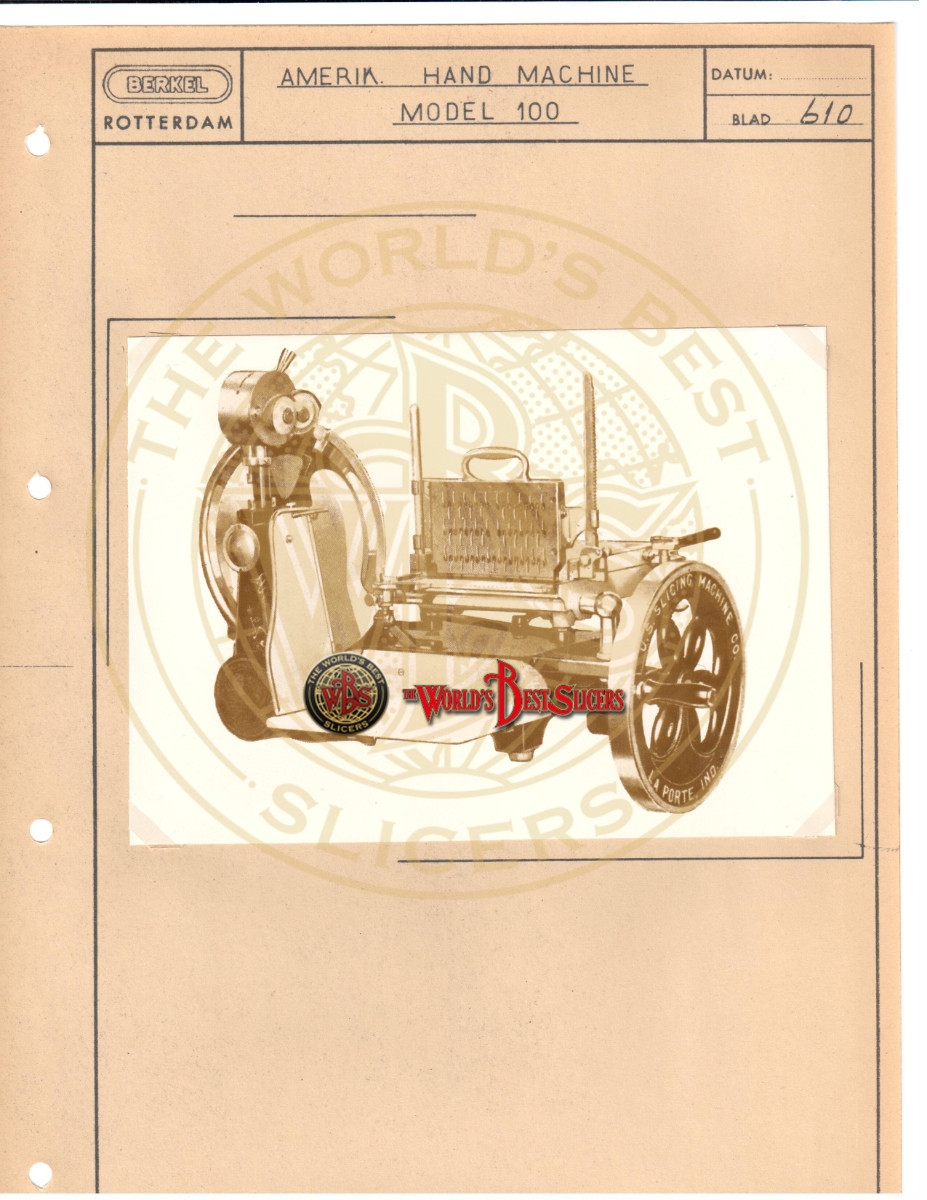

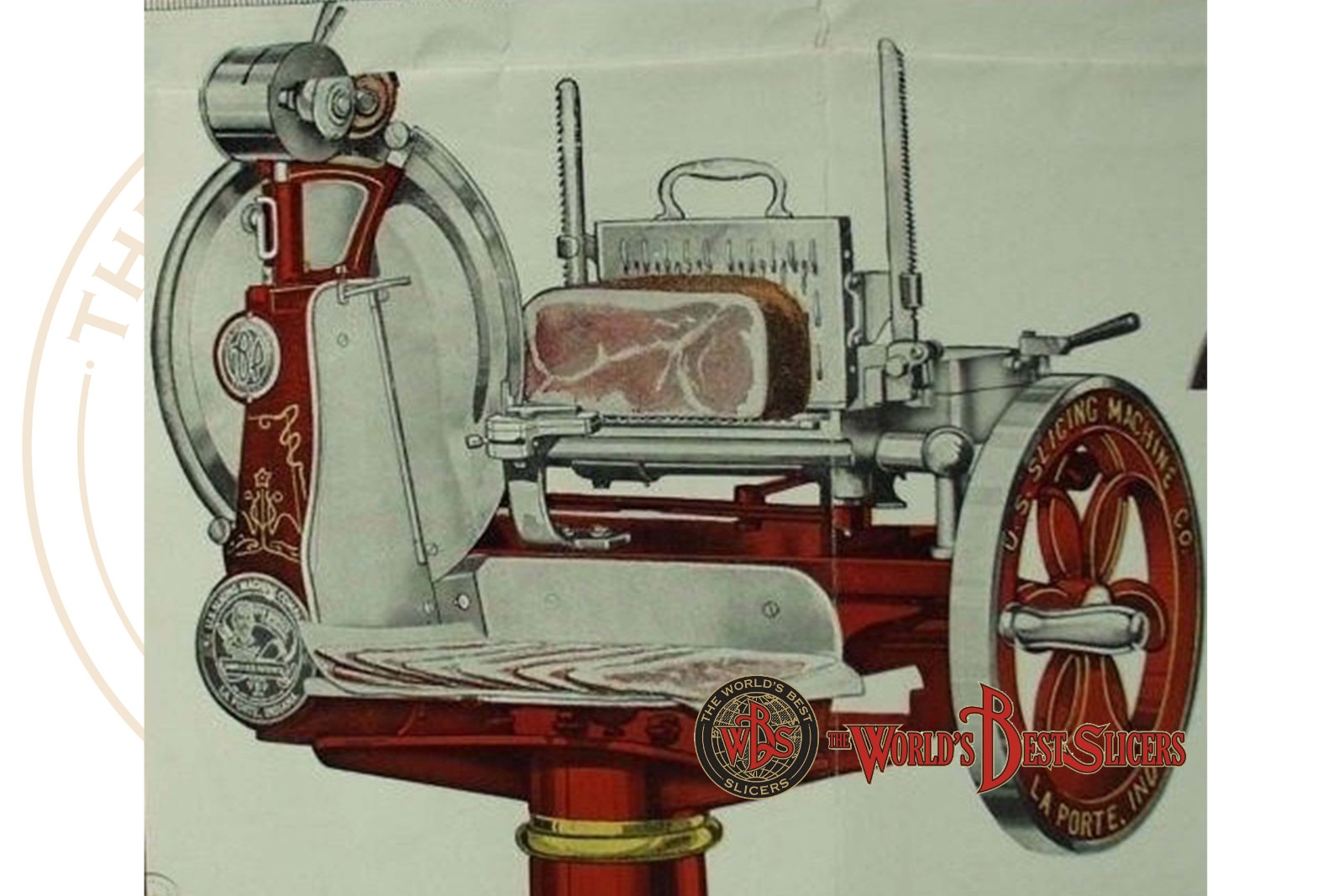

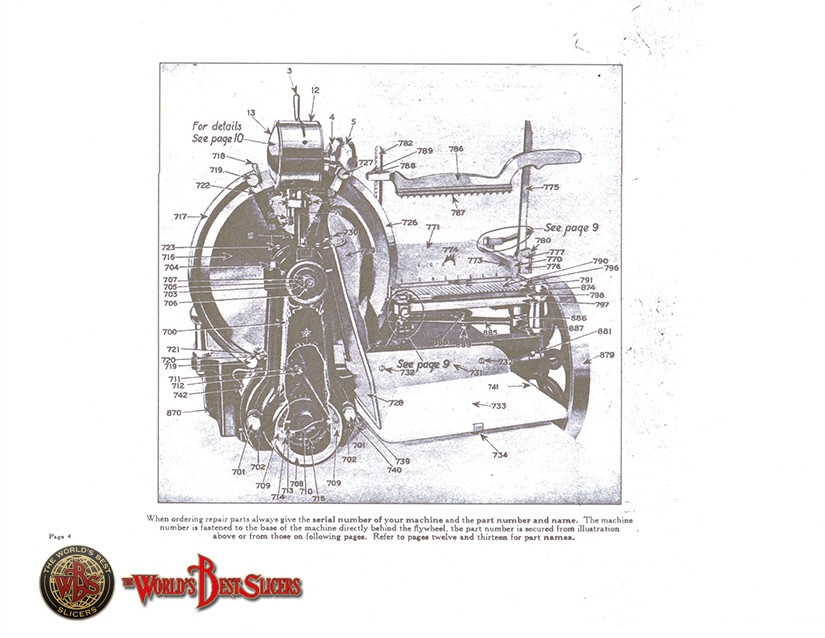

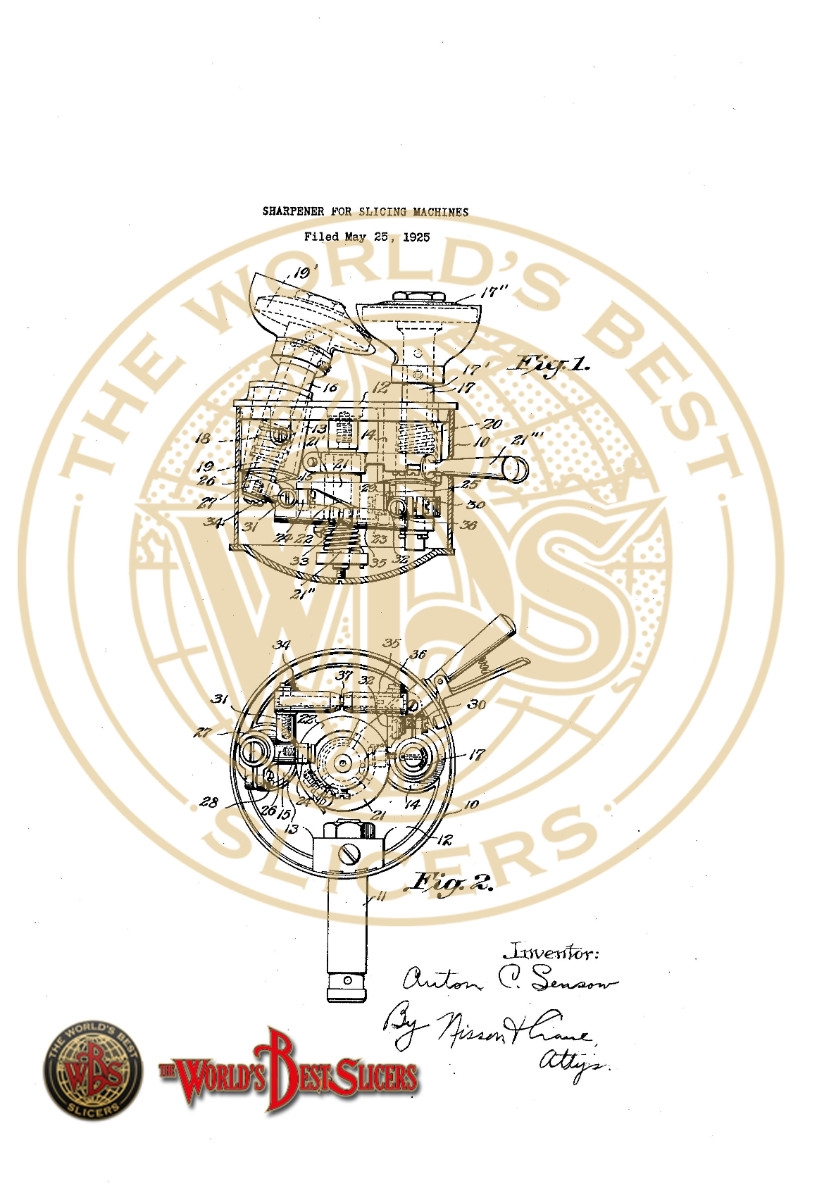

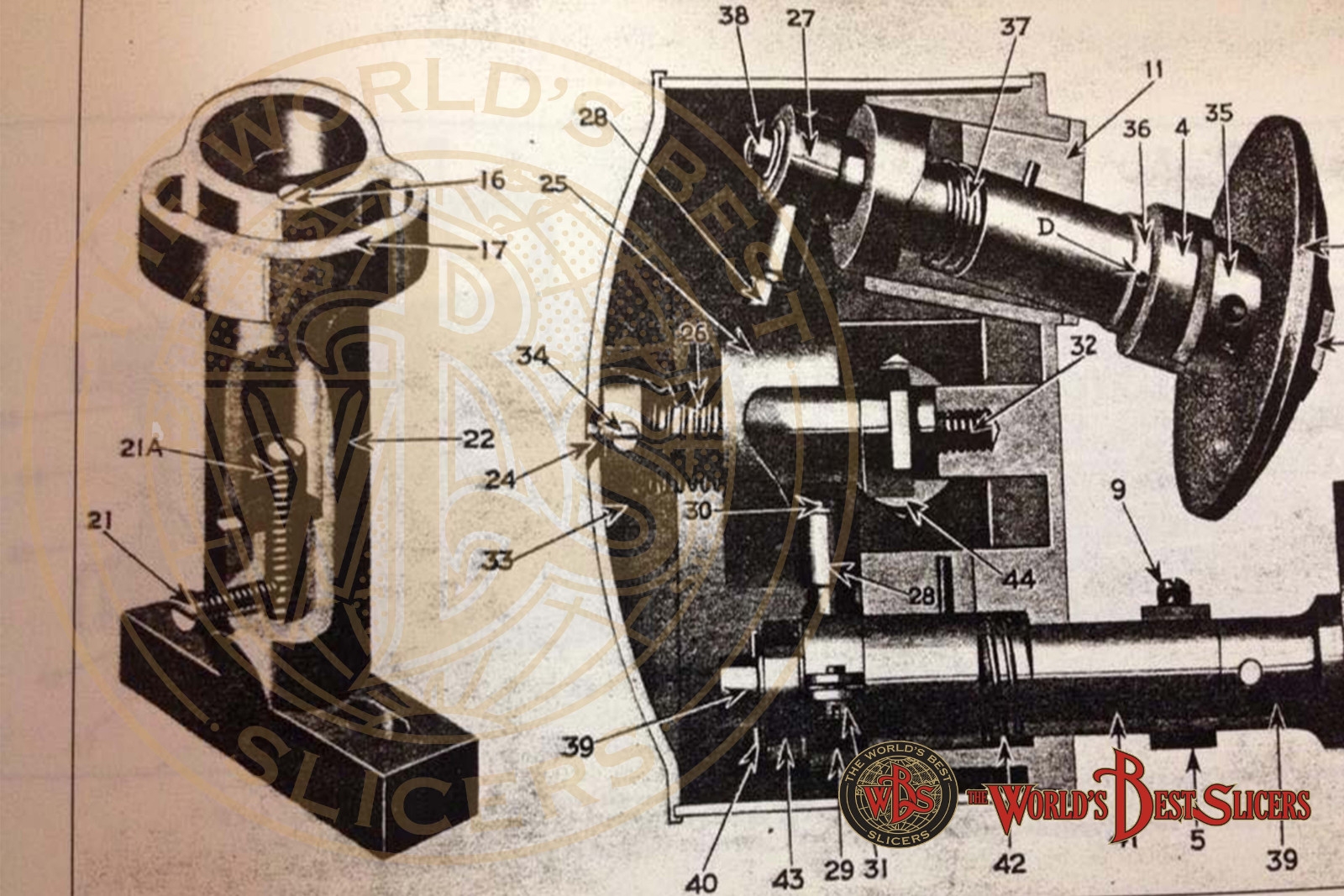

The flywheel slicer U.S. Berkel model 100 is built in the period from 1918 to 1925 in the factory of "La porte" in the state of Indiana. The model 100 has a blade of 350 mm. and 370 mm. of diameter depending on the period of production and is fixed on the shoulder where we also find the apparatus for sharpening the blade very characteristic of rounded shape and completely nickel-plated. In the lower part of the shoulder we find a round plate that depicts the face of W.A. van Berkel and indicates the manufacturing factory. By removing the fastening screws of the plate you can access a slot that allows you to see the screw for adjusting the chain tension and to intervene. The model 100 has a regulation of the thickness of the slice with 24 positions placed in the right side of the trolley, which through a lever gives the possibility to adjust the progress of the plate. On the left side, fixed on the body of the machine we find the white opaline glove where the cut goods are placed, while in front, applied on the shoulder is fixed the terminal part of the nickel-plated metal glove and the automatic parapet. The movement of the trolley is carried out by means of three connecting rods, of which the third which is smaller than the second fixed on the trolley is connected to a cam which is located on the right side of the carriage and with a whirling movement moves the arms that perform the movement of the sprinkler on the gear fixed on the worm screw. The worm is of six-principle type. The slicer mod. 100 is driven by a flywheel with a floral design with a external diameter of 368 mm. with the writing in relief "U.S. Slicing Machine La Porte Indiana" and it was produced in red and green and the metal parts are originally nickel-plated. The Berkel slicer mod. 100 has a total encumbrance of 840 mm. length 640 mm. width and 650 mm. height and requires a support of 280 mm. width. 500 mm. length. The slicer U.S.Berkel mod. 100 altogether weighs 112 kg. Also this model of slicer was installed directly on the work benches of the various butchers and shops, but further it was possible to purchase as an option its original pedestal.The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee