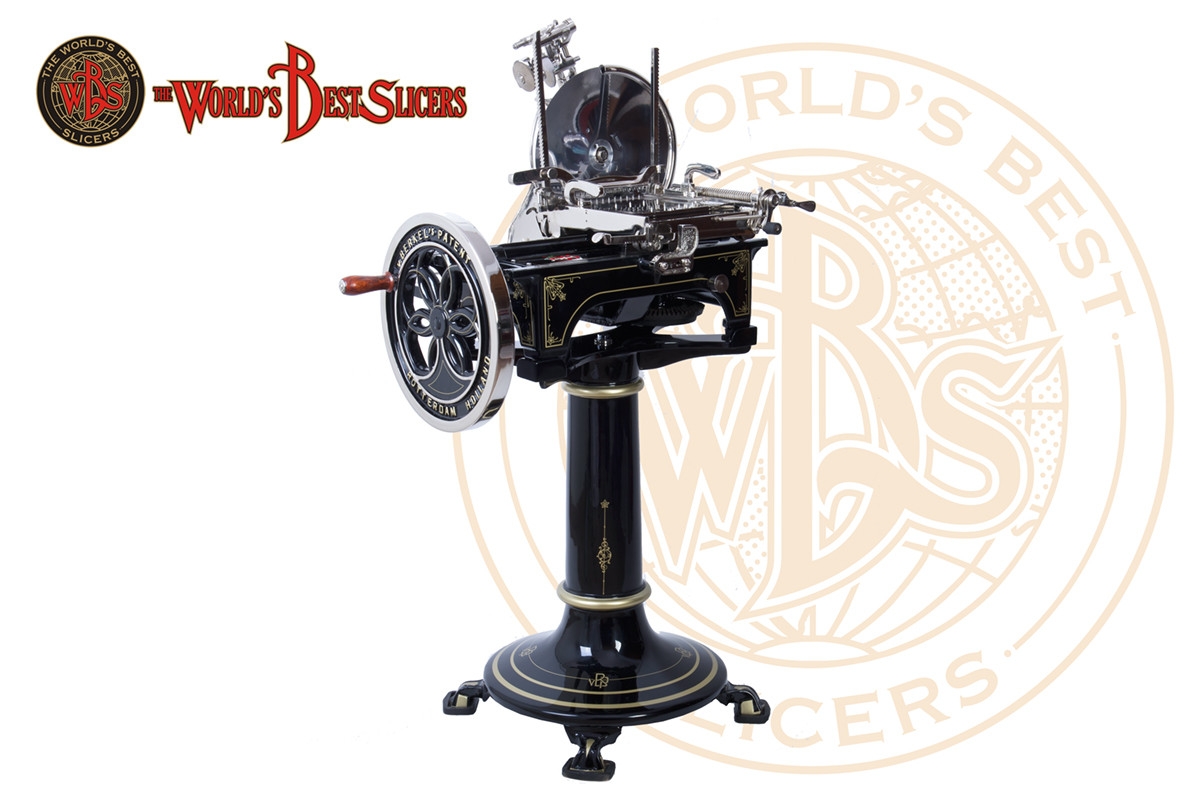

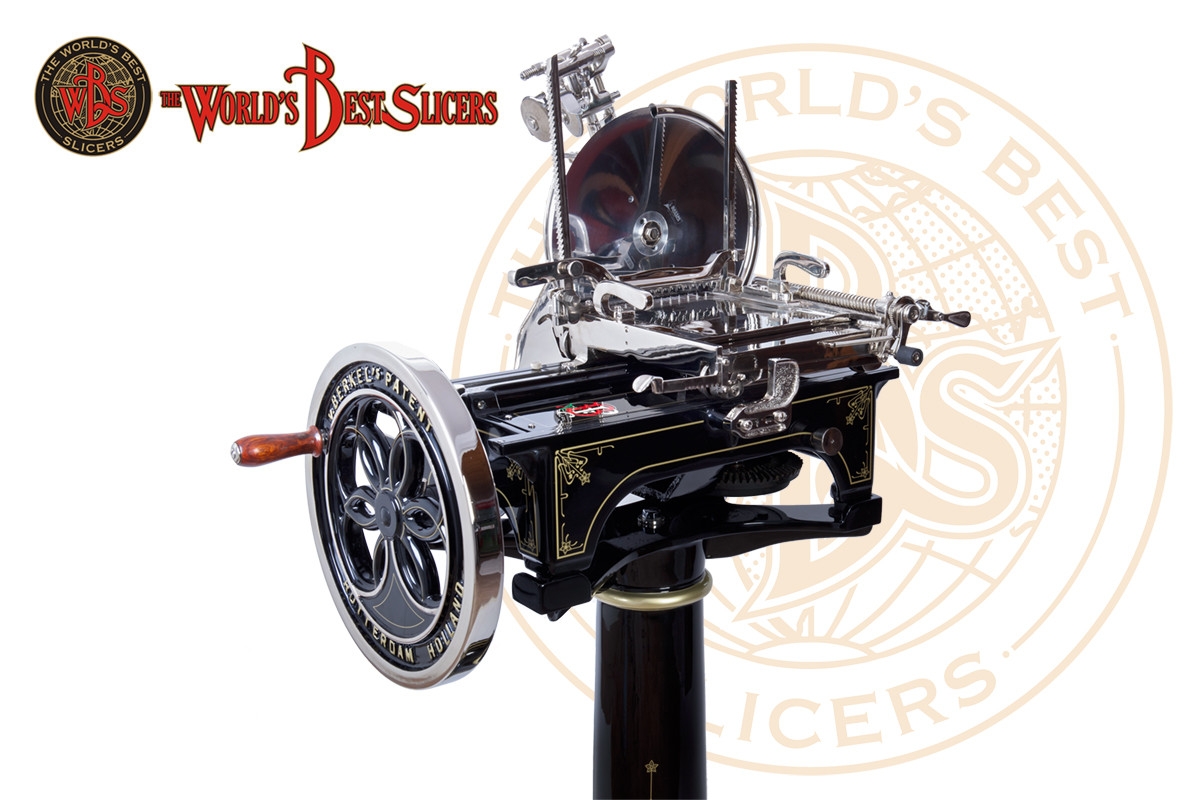

Berkel Europe Model L Black

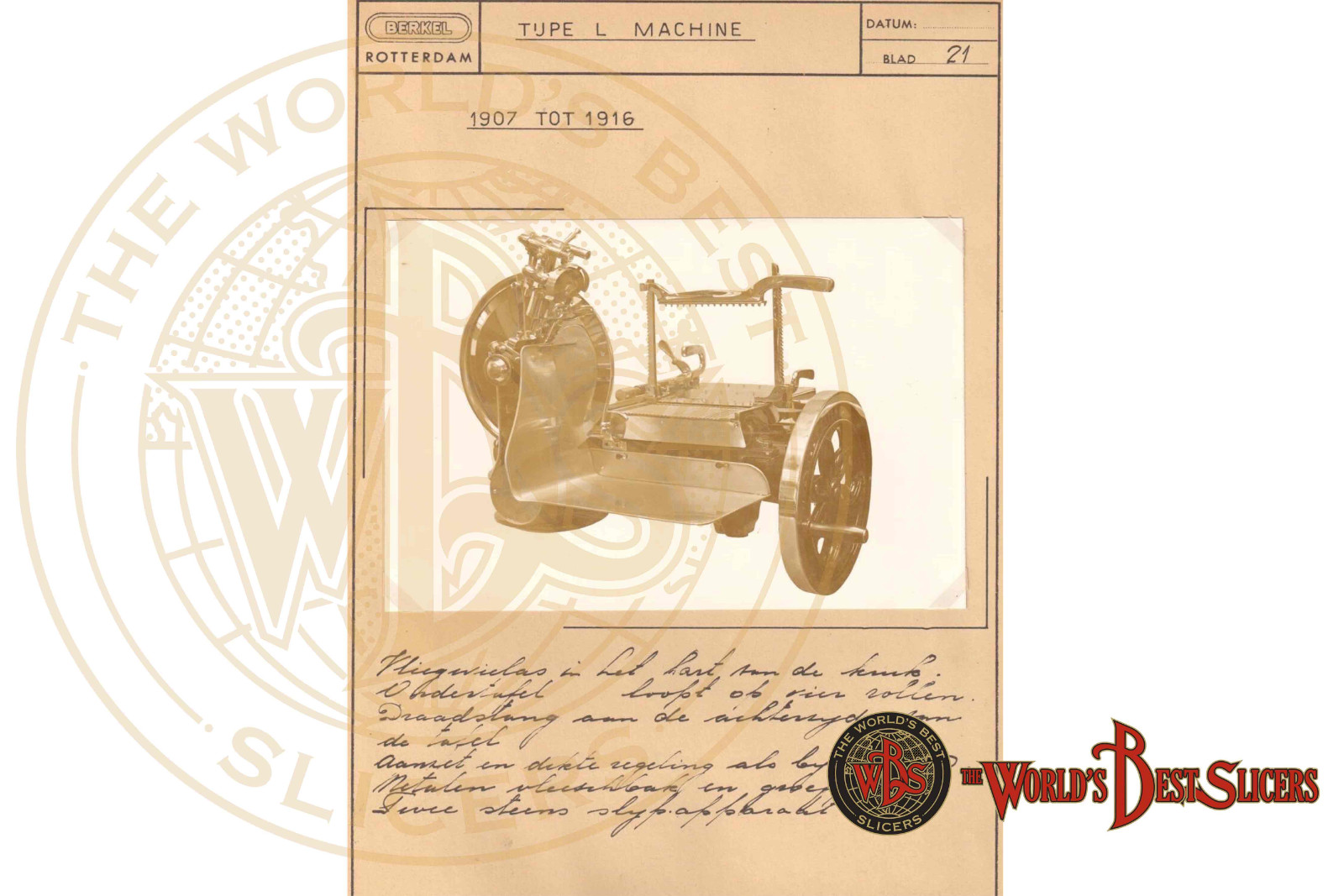

The flywheel slicer model L is built in the period between 1907 and 1916. The slicer Berkel model L is distributed in Italy at the beginning by BACH in Milan and later also in South America

Berkel Europe Model L Black

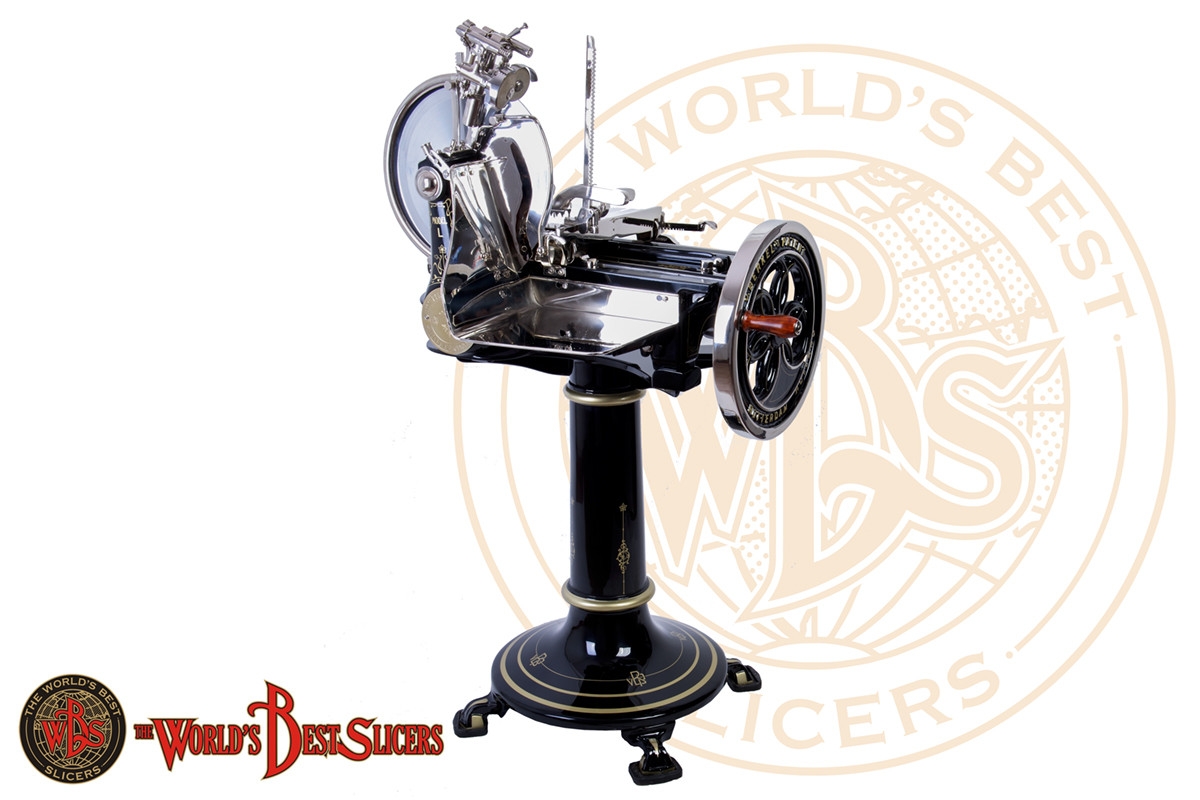

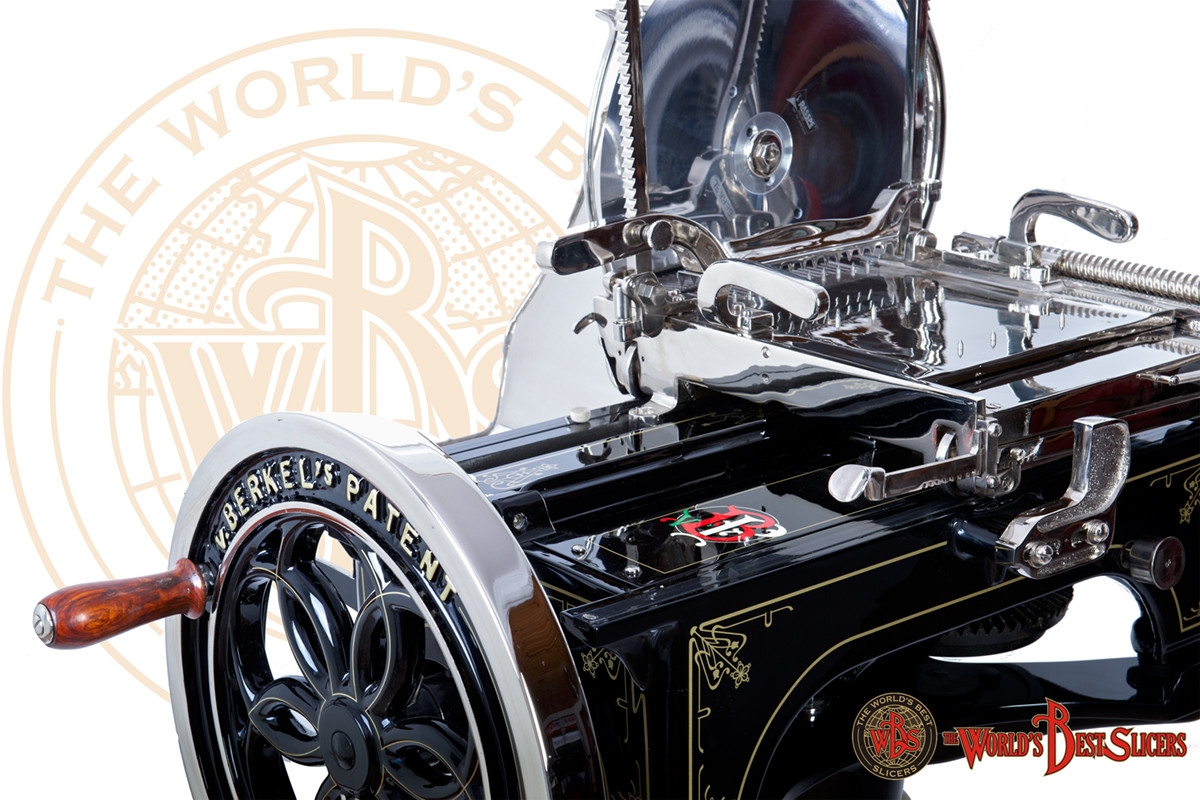

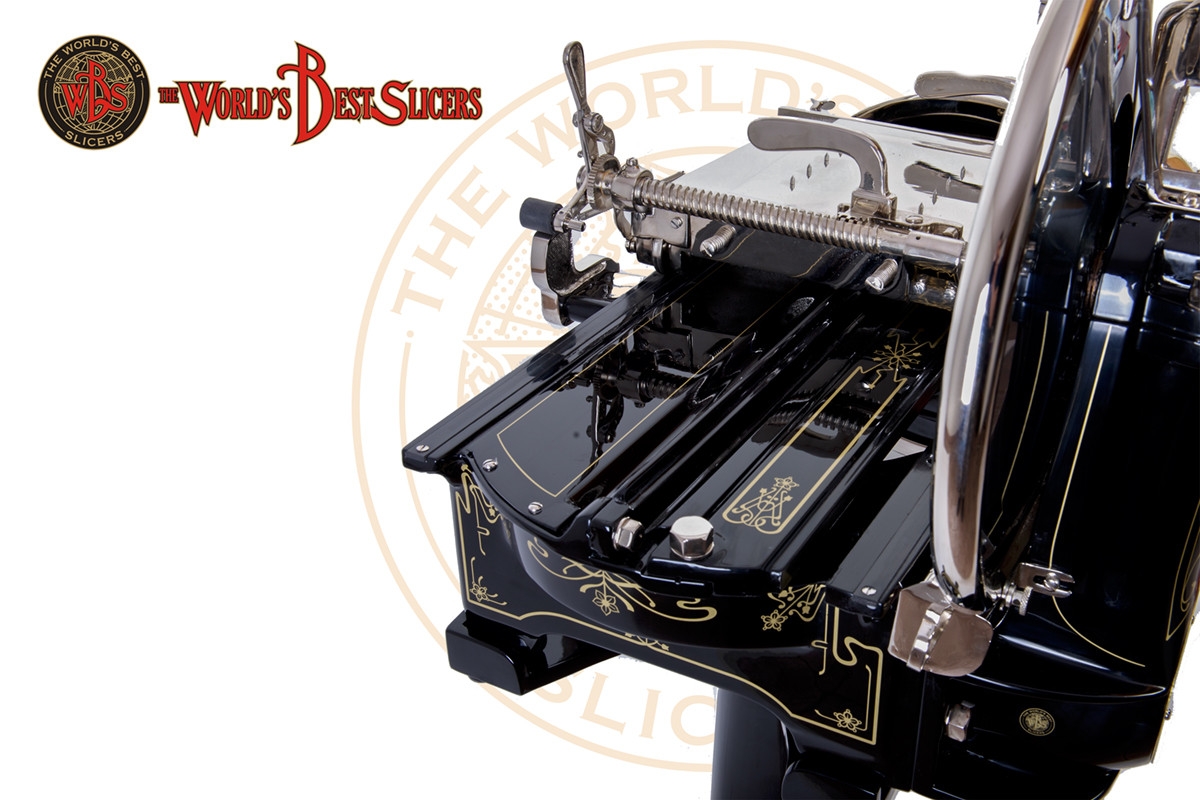

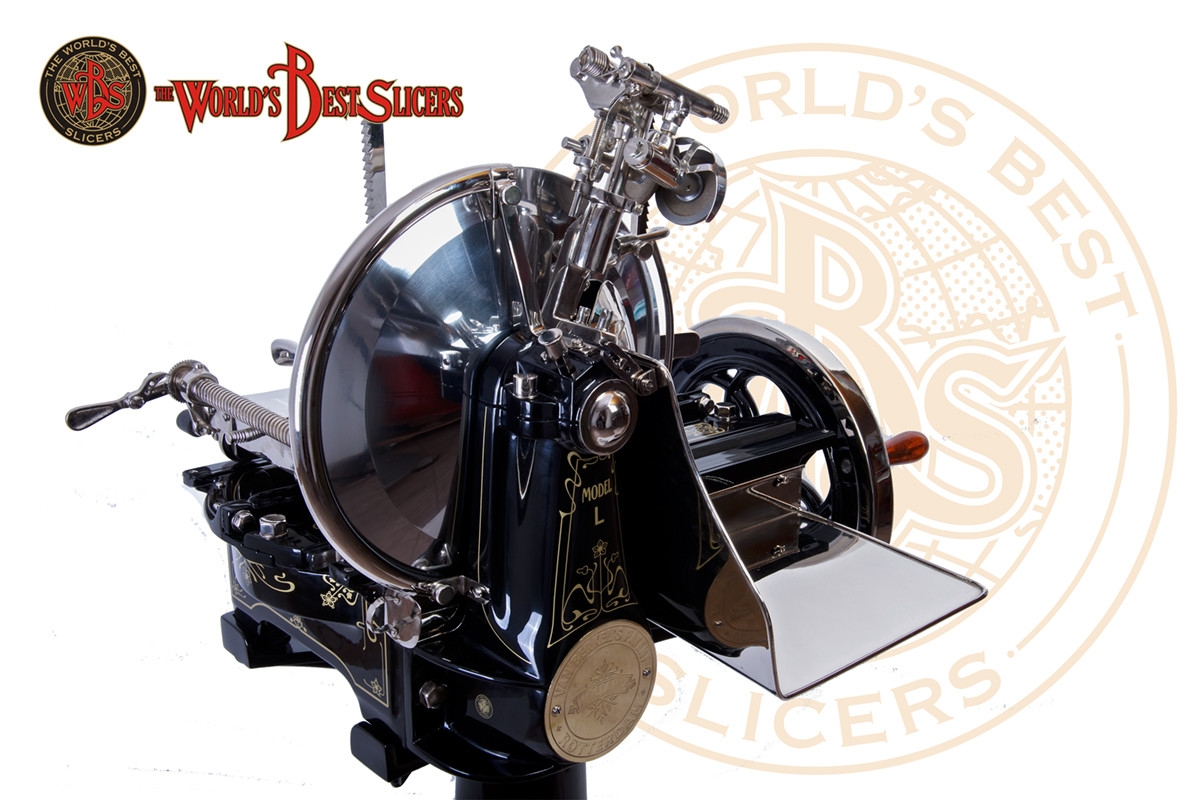

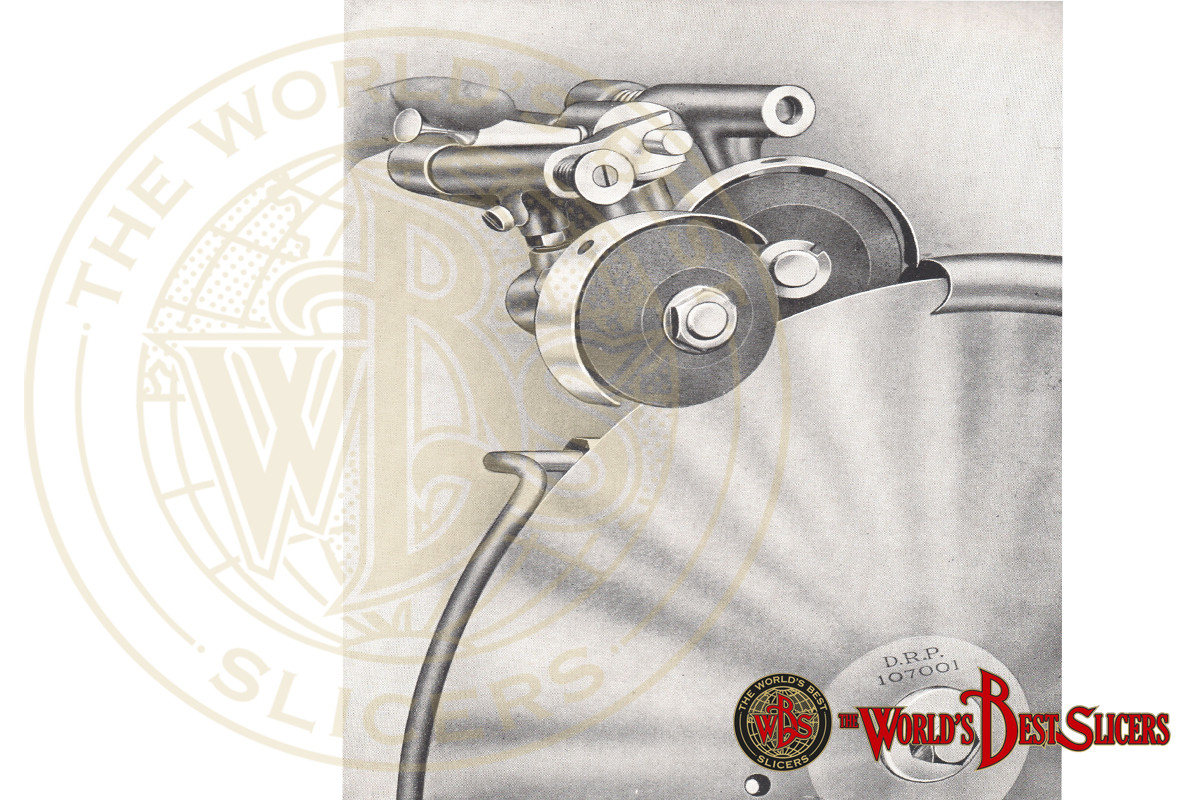

The flywheel slicer model L is built in the period between 1907 and 1916. The slicer Berkel model L is distributed in Italy at the beginning by BACH in Milan and later also in South America, where, in those years, was born Berkel Argentina.The Berkel model L in some features takes the model D, the movement is driven by the flywheel that has concentric circles that intersect thus forming a floral design.The professional slicer Berkel model L has always been an example of design coveted by numerous collectors all over the world for its beauty and for its remarkable fine cutting characteristics, which despite the abundant century of age, after a meticulous and careful professional restoration can achieve a fineness of cut equal to 0.2 mm. In the last years of production the slicer movement has had a greater fluidity thanks to a counterweight inserted in the flywheel. The flywheel activates the gear system that moves the blade and two connecting rods hidden under the body of the Berkel model L slicer that normally rests on its original antique pedestal. This mode generates the movement of the slicer. on four metal wheels that slide on guides on the body of the slicer made of black bakelite. The arm, or press used to fix the product to be cut, has its movement between two opposing racks. The regulation of the thickness of the slice is carried out by a graduated numbered 15-position rod that slides through a slit on the right side of the trolley, connected by a small lever to the gear that creates the displacement of the plate where the product to be cut is fixed On the plate where the product destined for cutting is fixed, the comb is fixed directly on sight, which serves for the regular movement of the product towards the blade through the movement of the worm screw.The plate in the upper part of the slicer unit is also characteristic, which is only present in some of the first models produced by Berkel of black color without distinction from the rest of the slicer, where a fine square of gold is decorated and in the part opposite the fly the abbreviated logo of the manufacturer VBP print in decal of red green and white color. The blade, of 350 mm. , is fixed on a shoulder whose lower part is round and to which the metal glove is fixed to support the cut product and in the lower part with a round shape, a small plate is placed by two screws , with a different design and description according to the countries where Van Berkel's Patent was marketed by VBP. At the top of the shoulder we find the blade sharpener, made up of several nickel-plated pieces, all visible and without covers. The Berkel flywheel slicer model L considered a professional flywheel slicer. The Berkel Model L slicer has a total dimensions of 835 mm x 660 mm, is 630 mm high and weighs 101 kg. The Berkel mod. L needs a 490 mm front support X 310 mm. The Berkel slicer model L was produced in red, ivory, black color and the metal parts are nickel-plated.The slicer was normally placed on the workbenches, but optionally the original pedestal was placed where the slicer was placed, which was initially decorated with coppal paint decals with purely Art Nouveau designs depicting flowers and leaves, then the design is be more sober with concentric circles with the application of the initials VBP in the innermost part, while in the lower tubular section were applied decals depicting stylized stem flowers.The slicer was supplied without any supporting support, but optionally at the request of the buyer his original pedestal was supplied, where the slicer could be correctly positioned in every point of the room without creating impediments on the work and be cleaned more easily and be enhanced even more. This slicer, like all the flywheel slicers that have been restored and sold by The World's Best Slicers, is restored exclusively with the exclusive use of original antique decals respecting the color tone and supplied with its original pedestal, avoiding trivial copies. The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee